Technical parameters

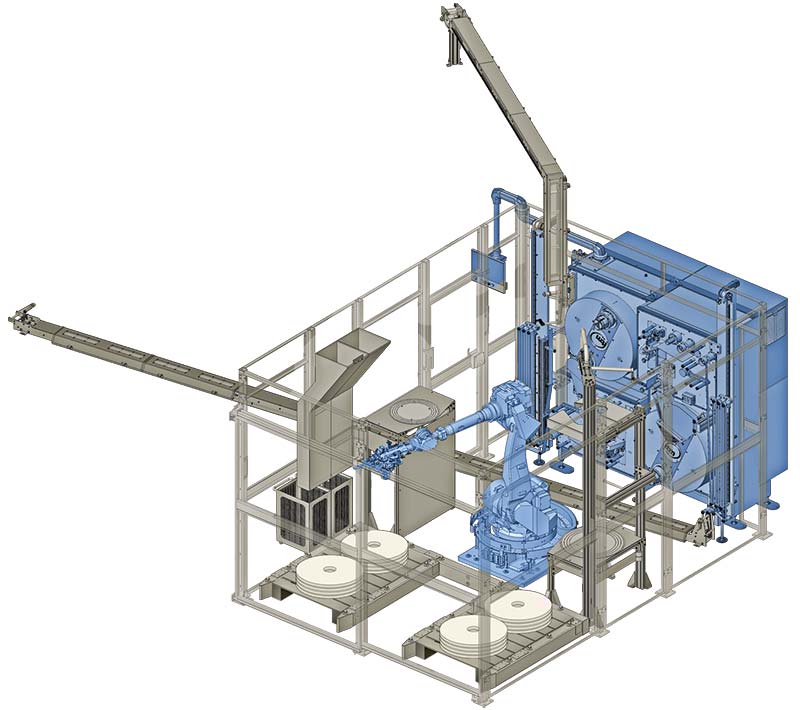

The Dual Bobbin Feeder (DBF) is a fully automated and integrated with a robot system of feeding paper for cigarette wrapping and tipping. It is integrated with the machine producing conventional cigarettes, filters, or new generation products. Many activities are performed automatically. After checking a bar code and paper orientation, paper bobbins are taken from a palette and then fed to the DBF machine. A paper band automatically passes between the rolls and is prepared for splicing. Following this process, the rest of the paper and plastic discs from used bobbins are automatically rejected. A great advantage of the system is no need of the operator’s participation in the whole process due to automation to automation of all the process components

Dual Bobbin Feeder®