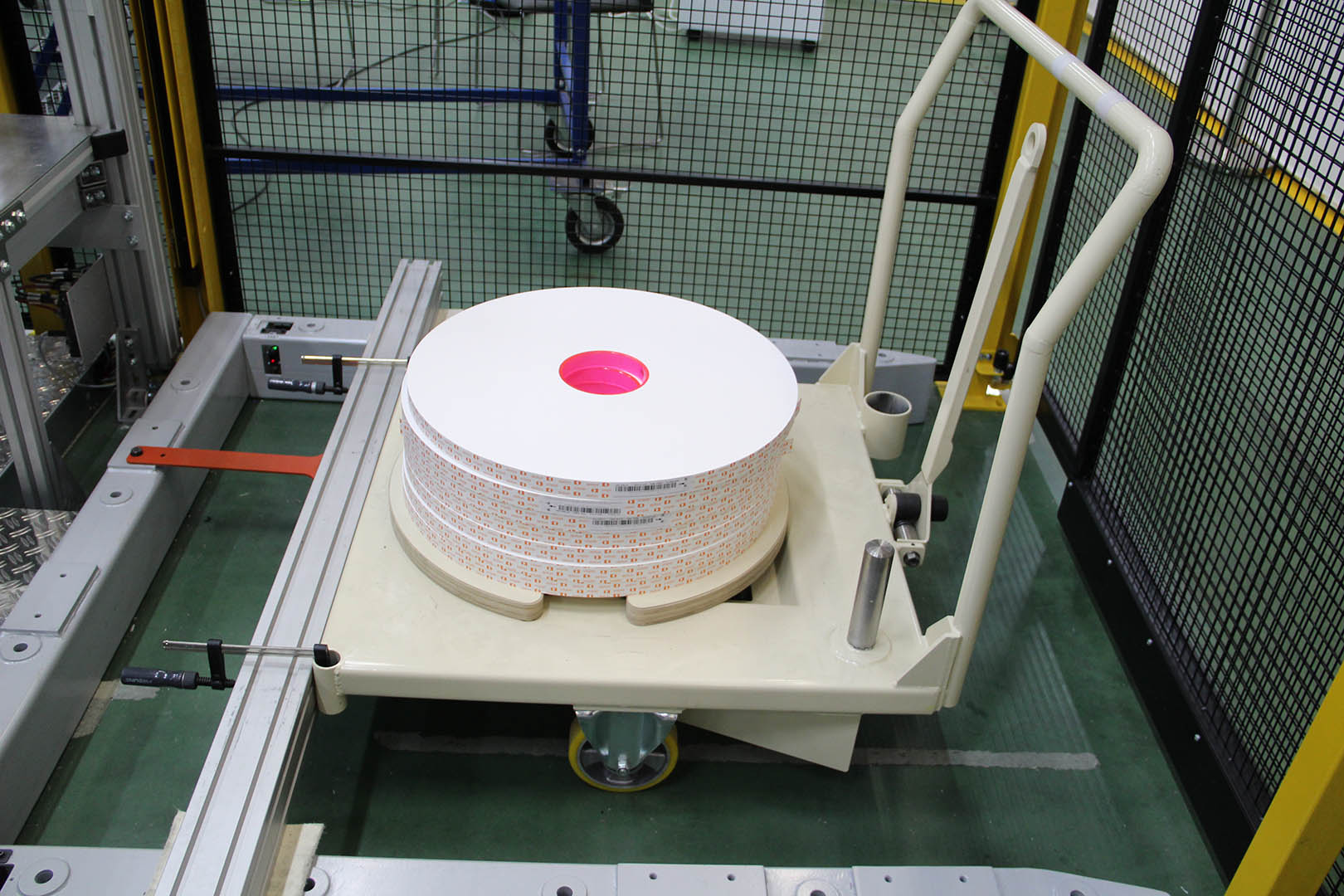

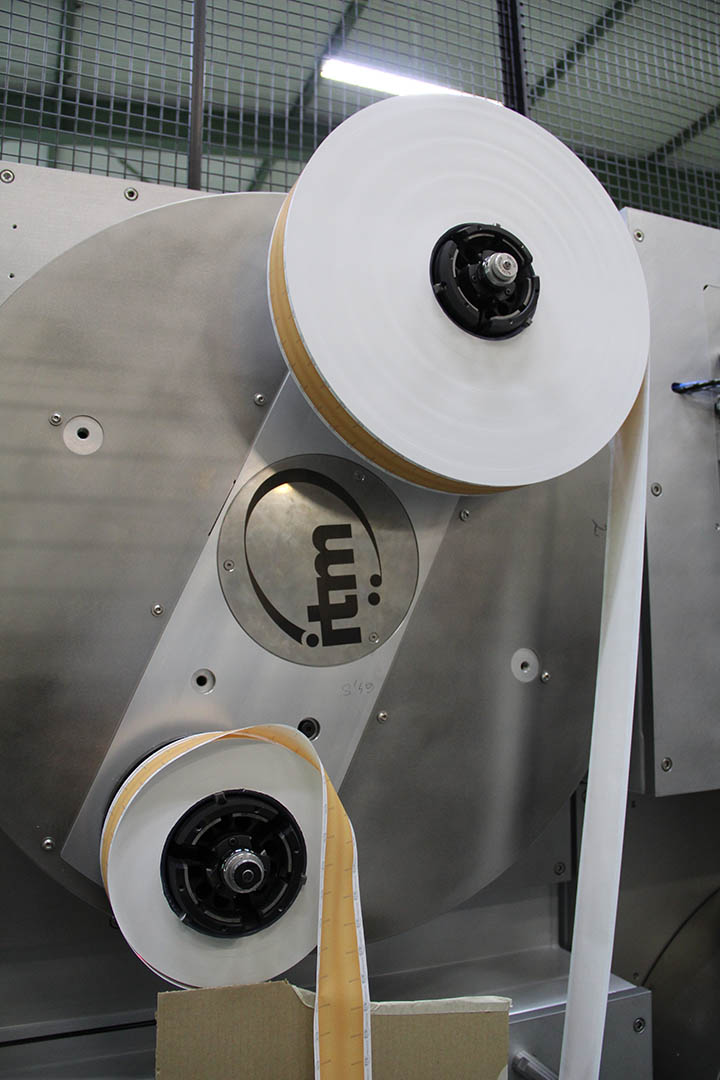

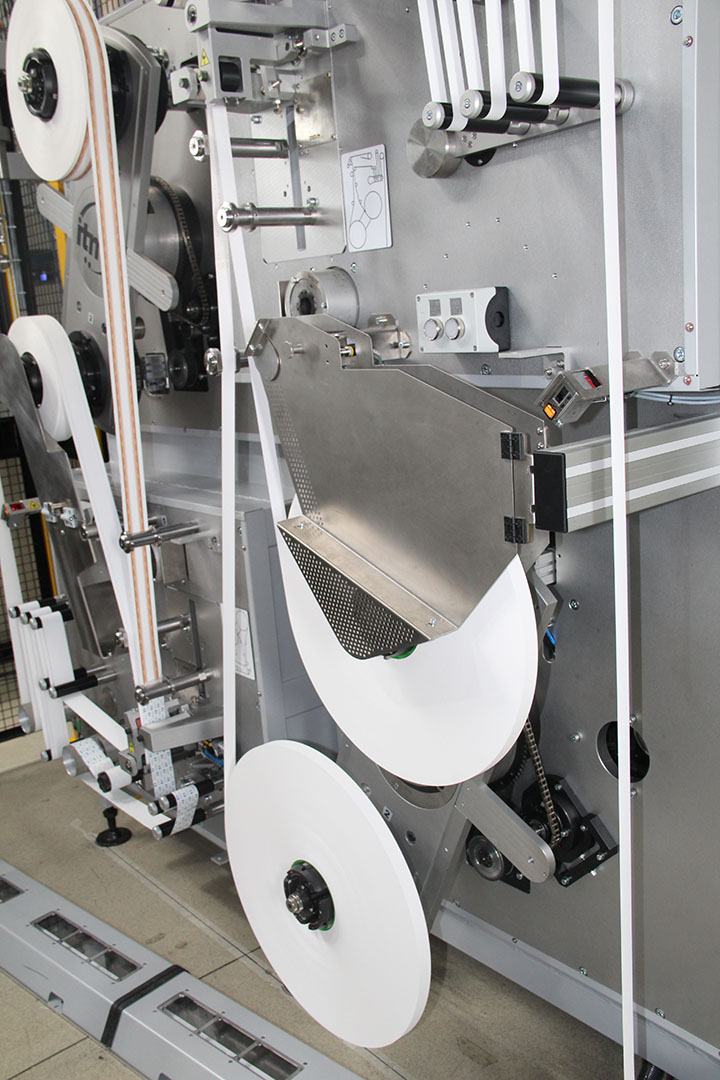

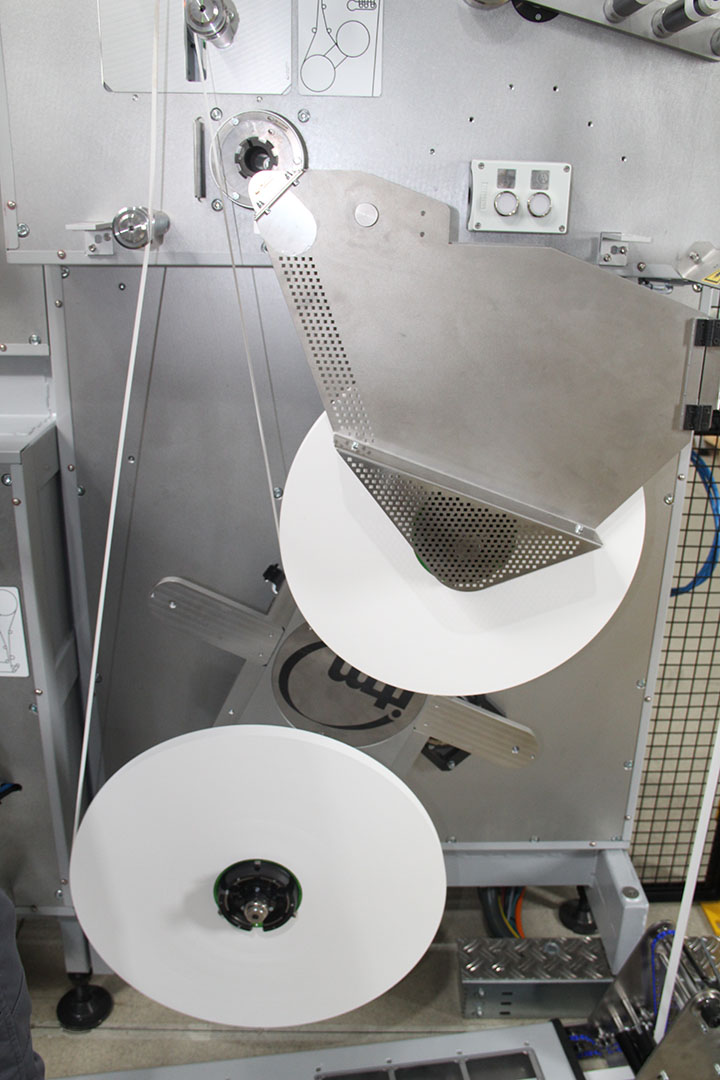

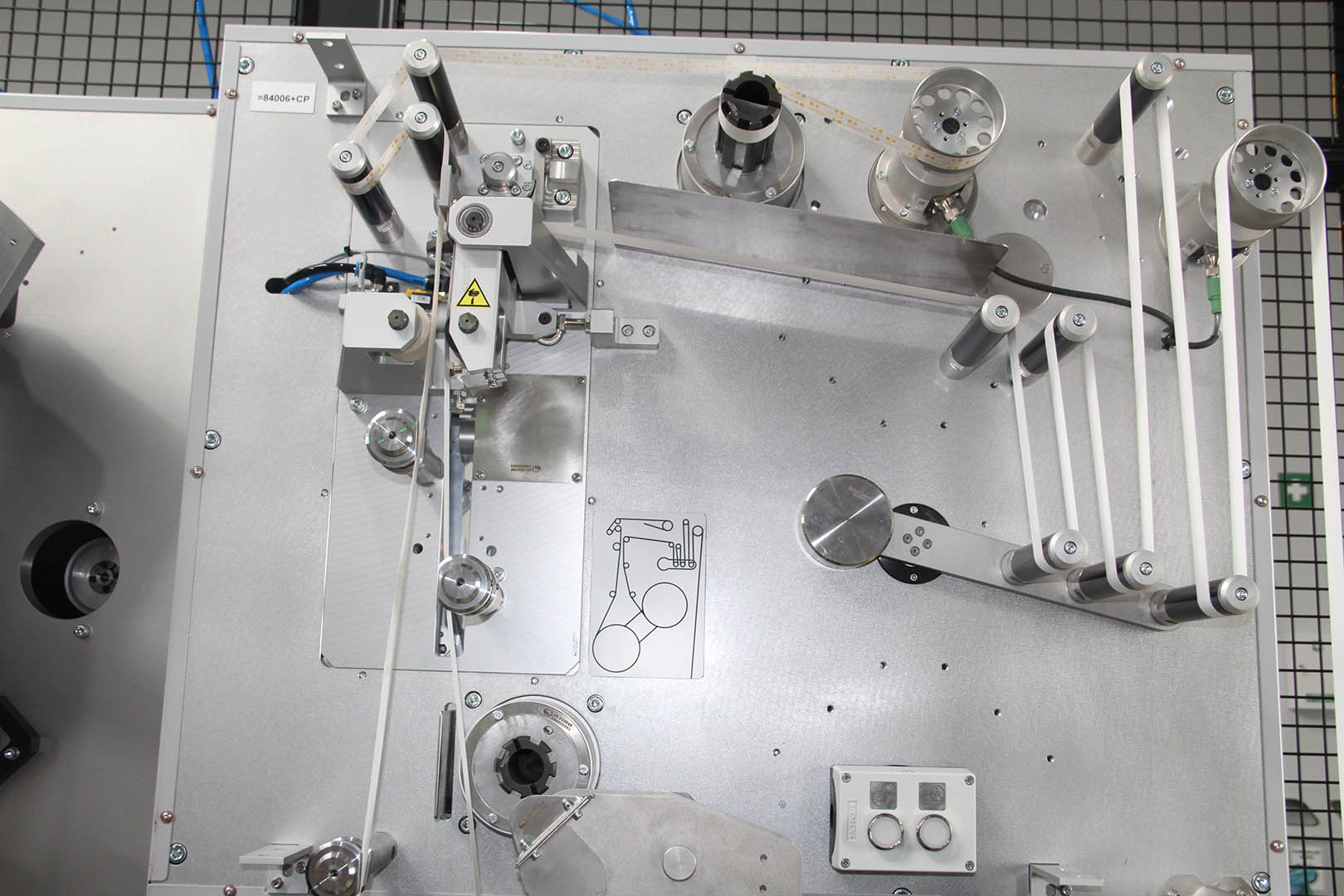

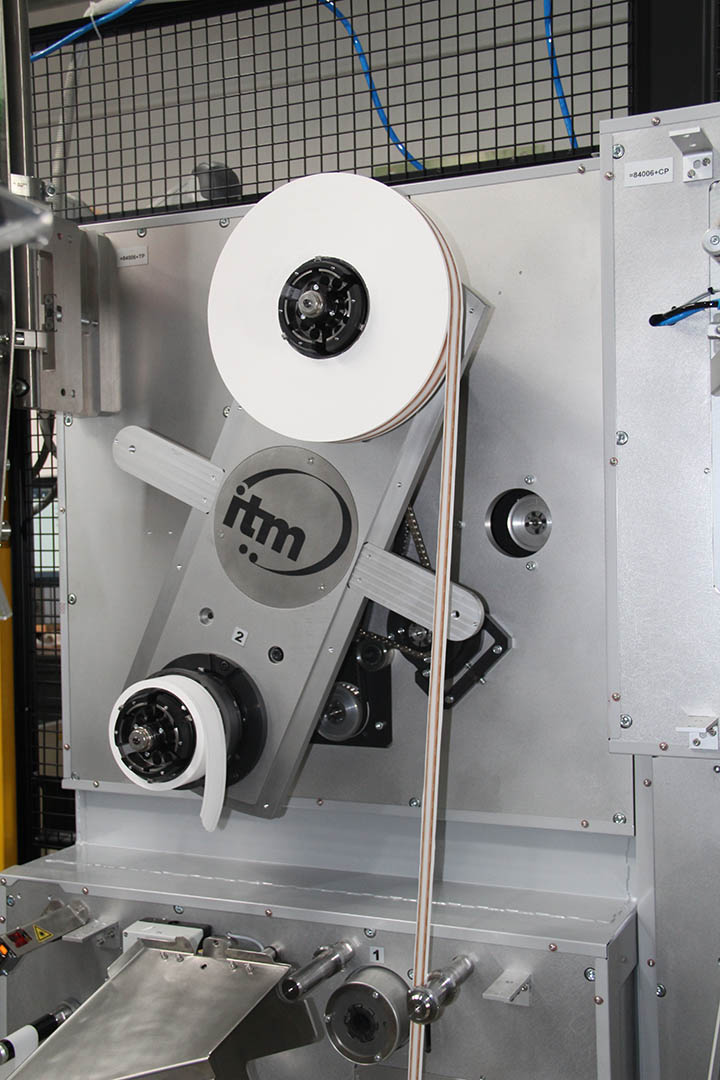

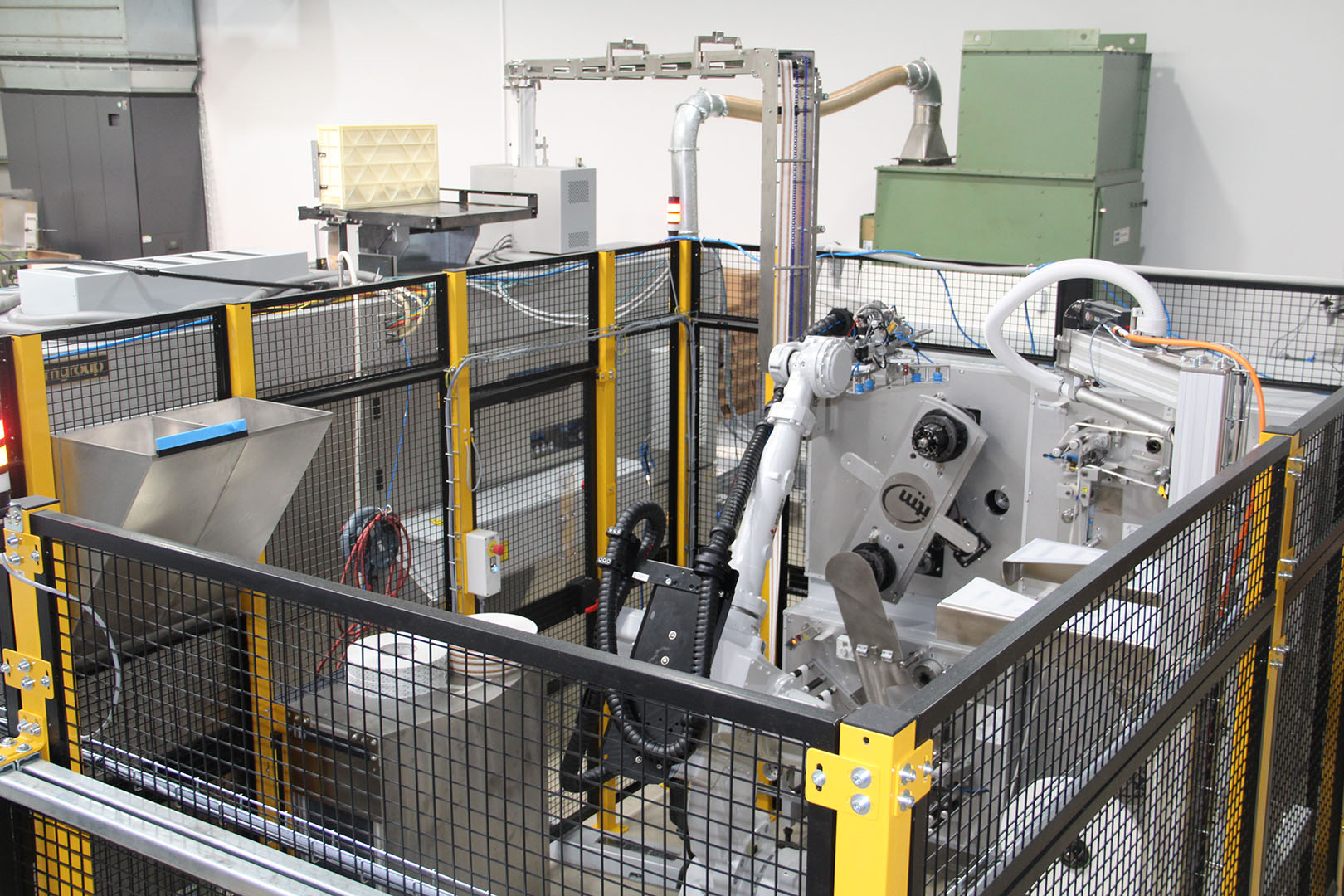

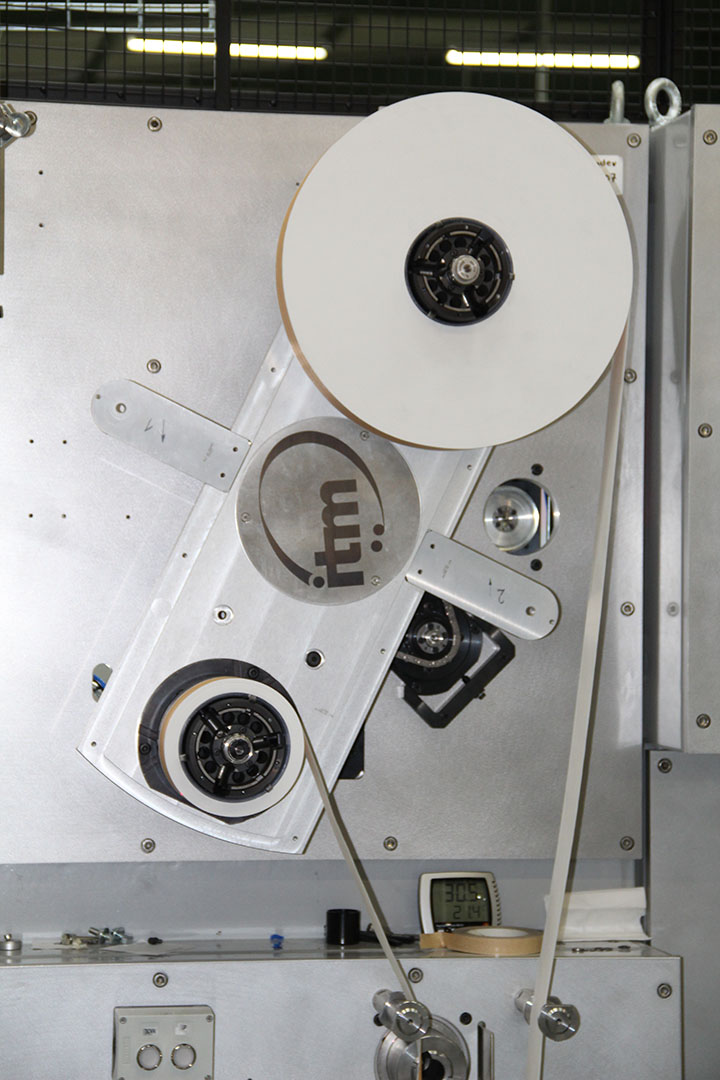

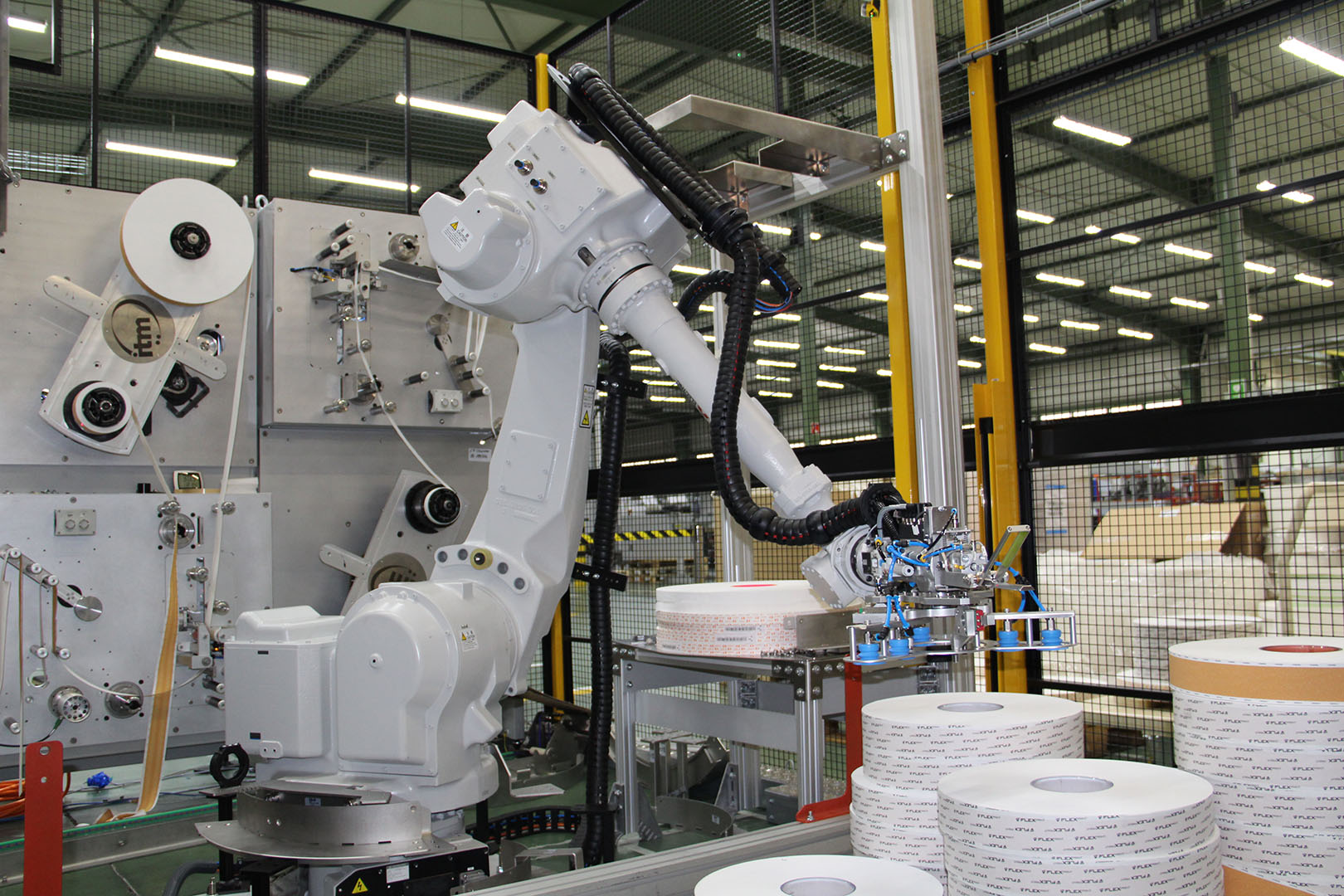

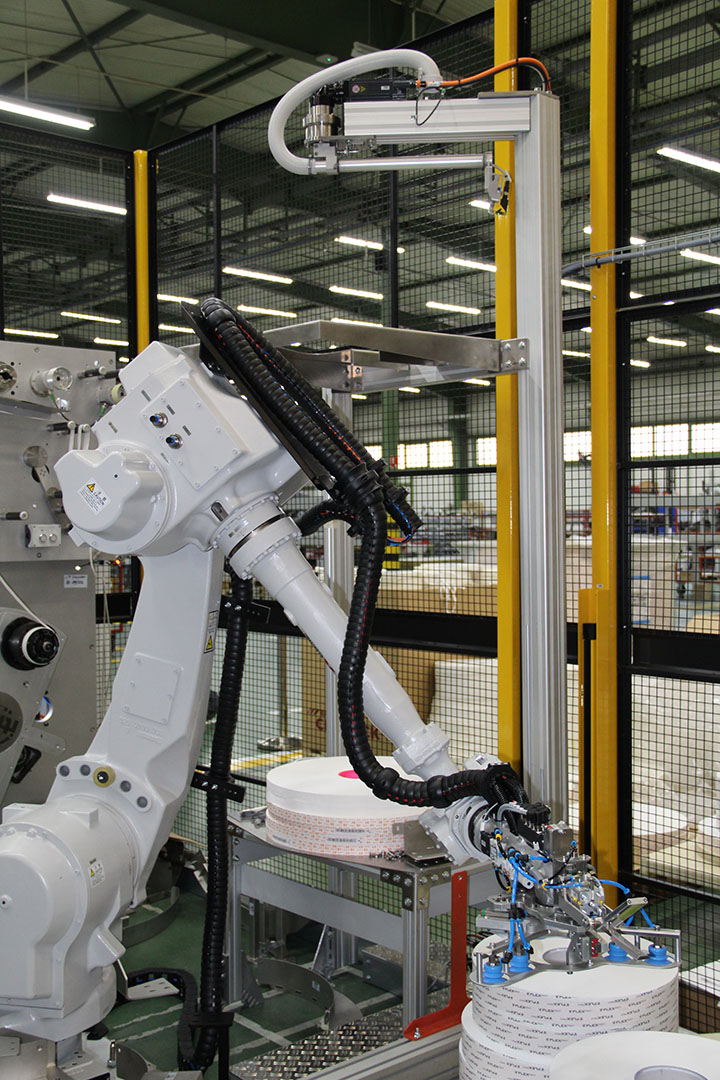

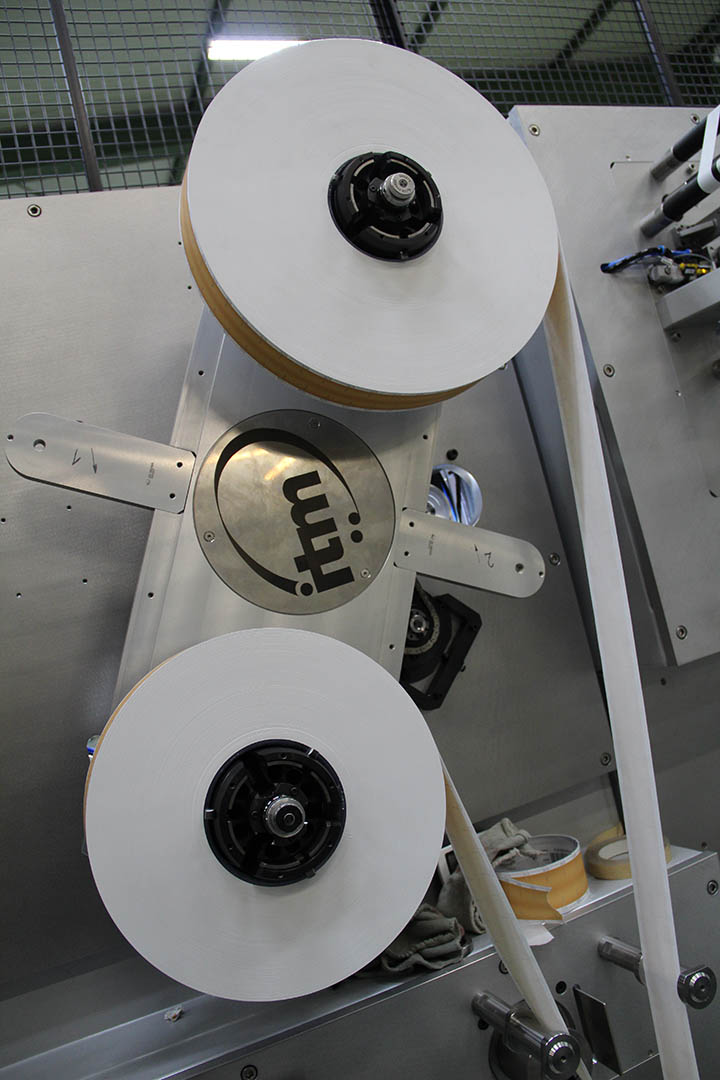

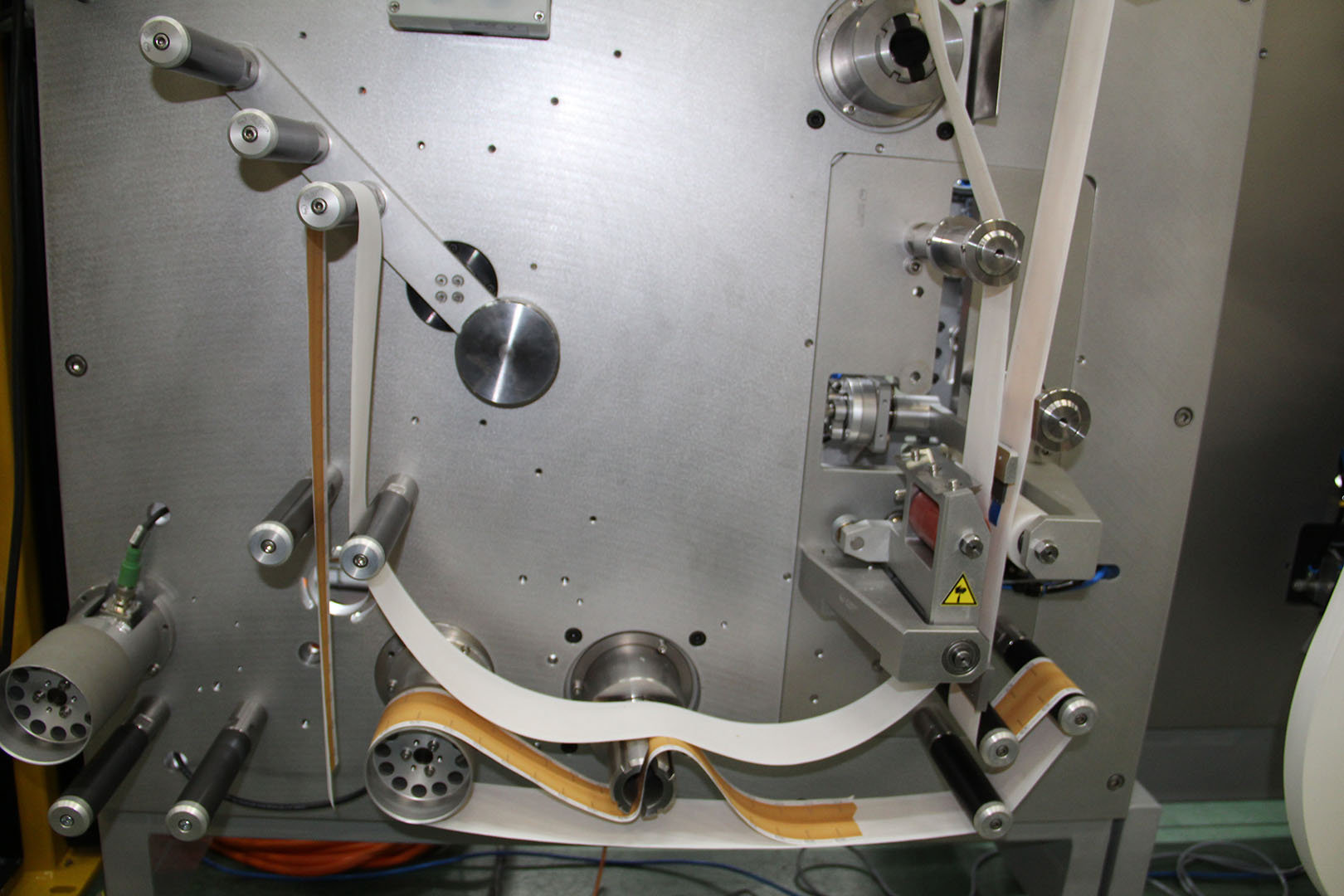

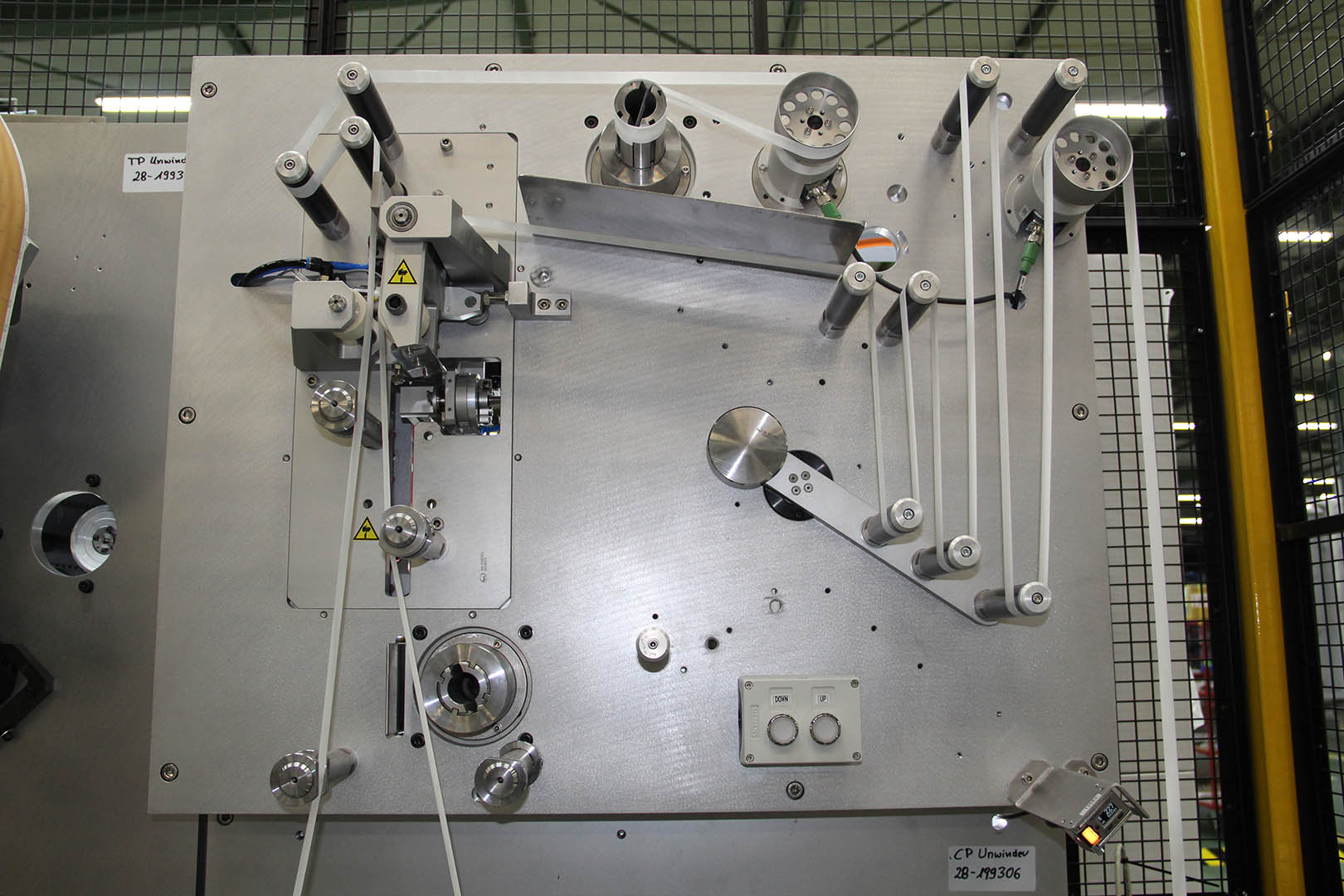

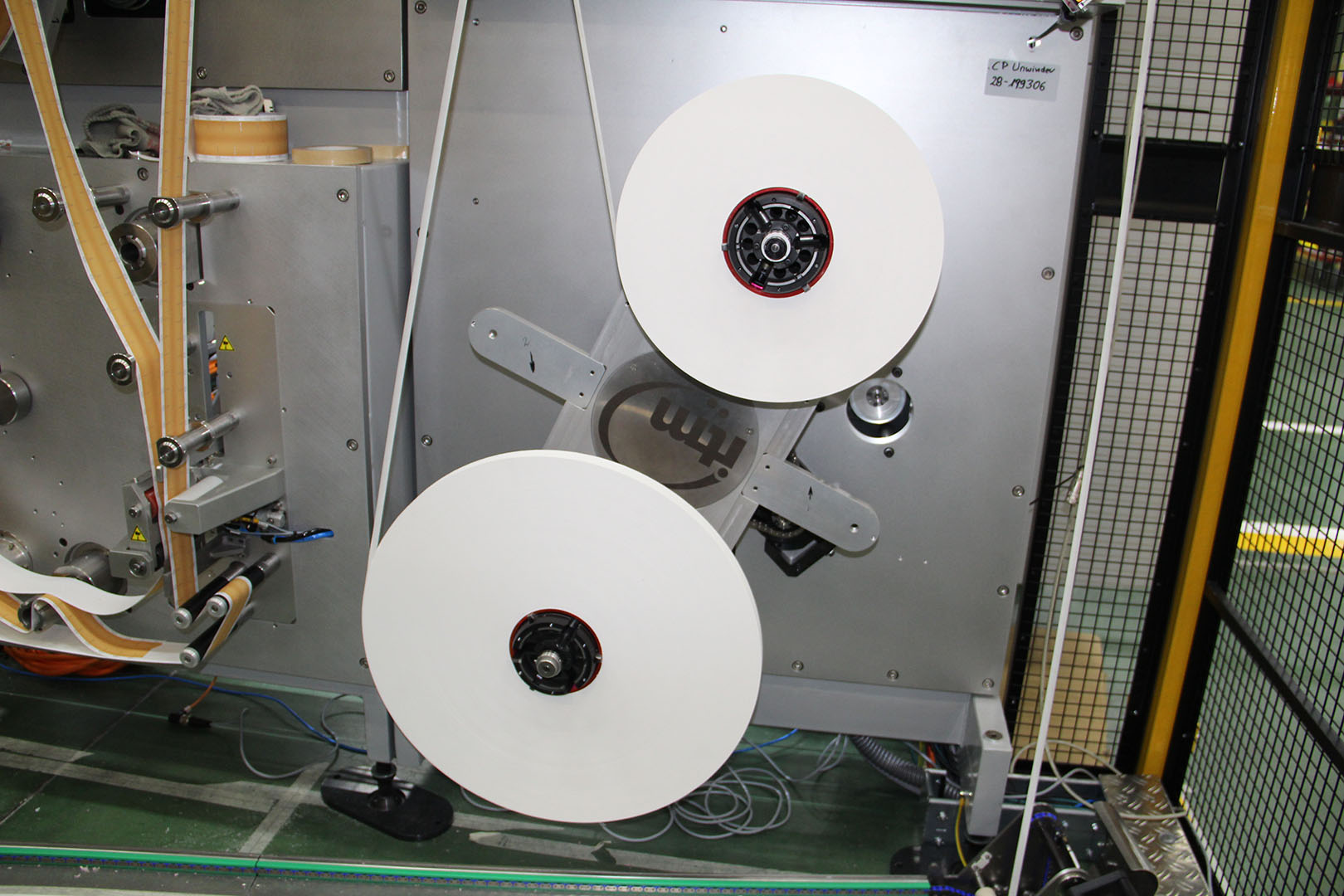

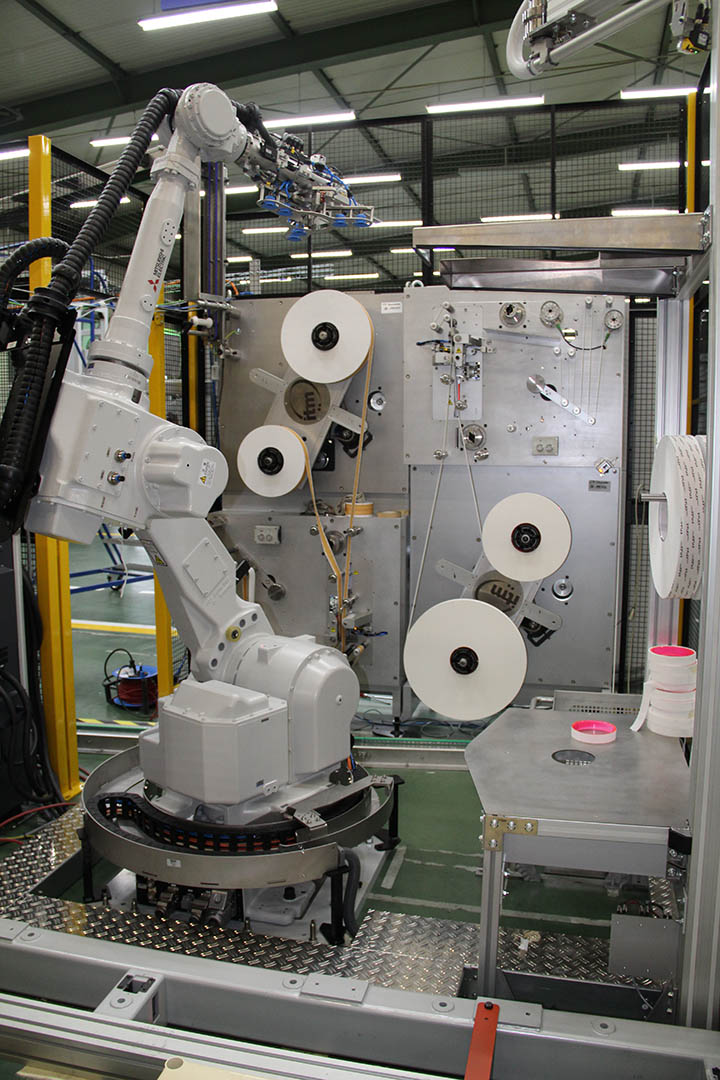

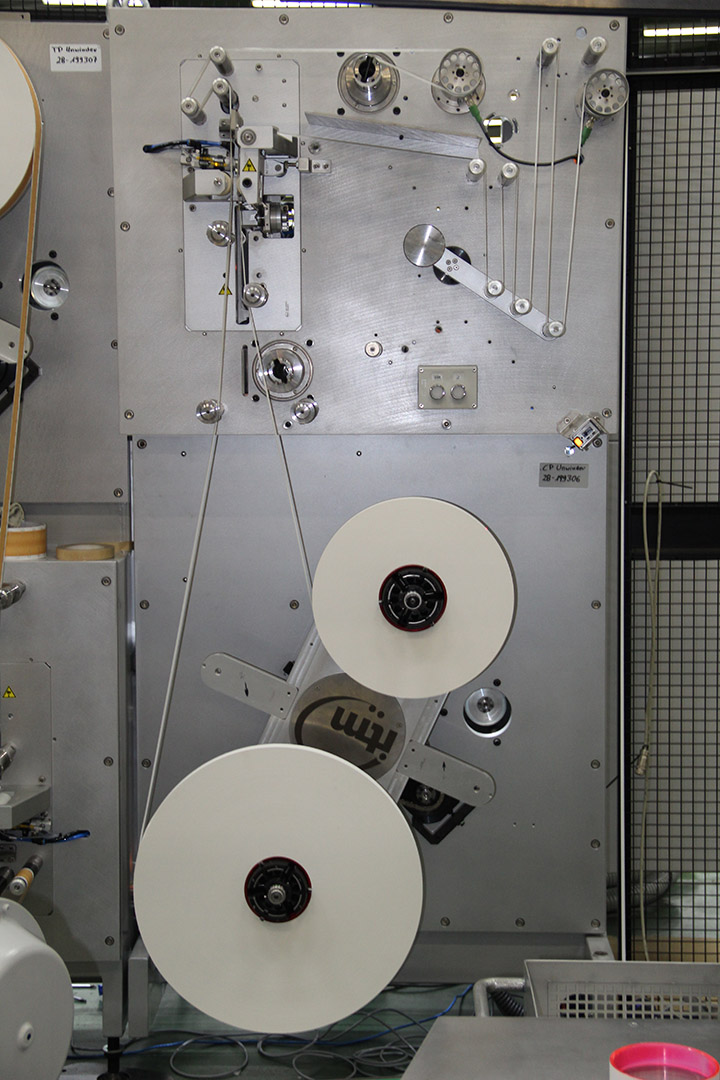

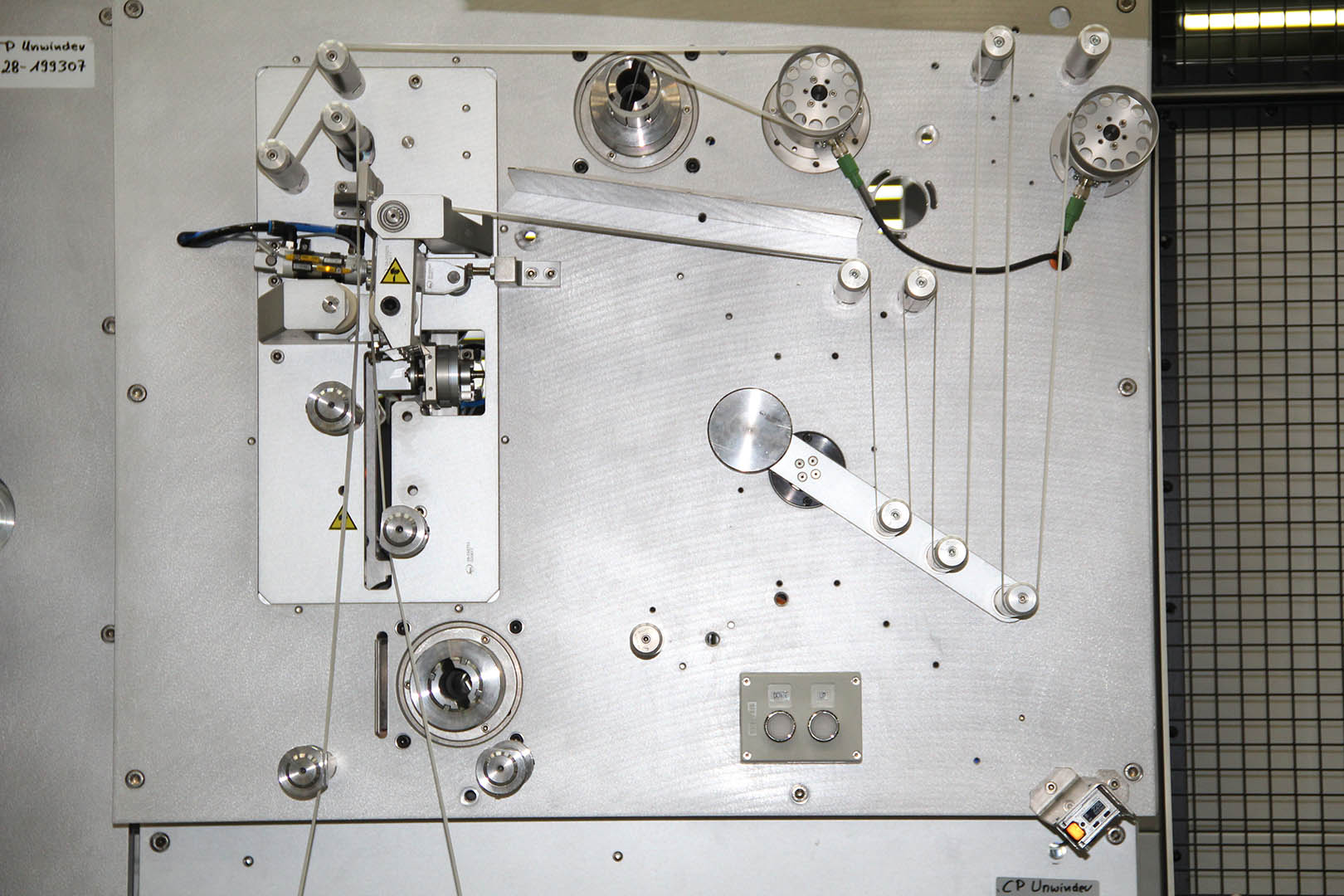

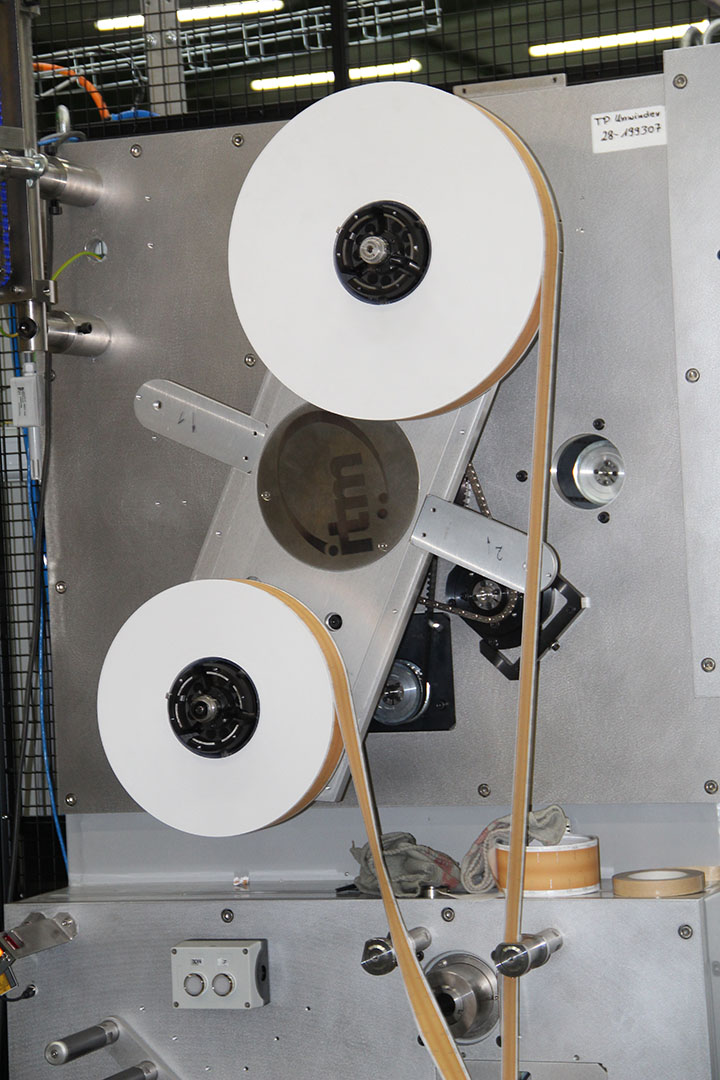

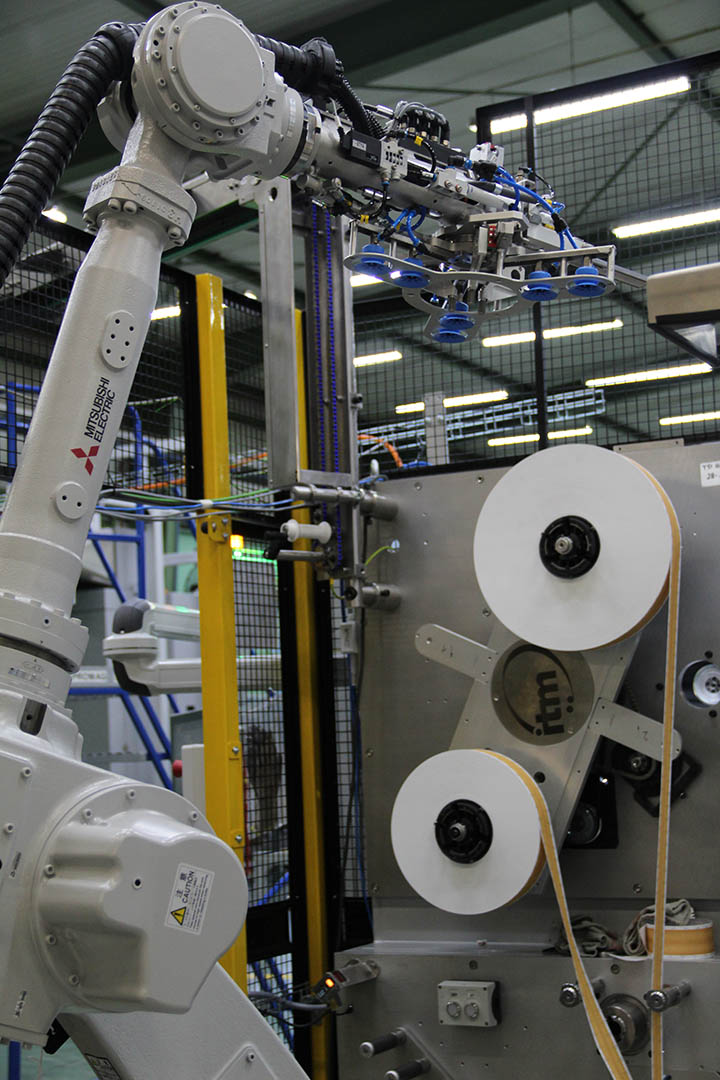

ITM Dual Bobbin Feeder (DBF) it is fully automated solution, integrated with the robot, for wrapping and tipping paper delivery. It is truly compact machine feeding two types of papers: wrapping paper and tipping paper. DBF can be easily located in standard Make-Pack or NGP lines. It ensures full flexibility in handling various types of papers due to their: weight, width and grammage. Thanks to the use of automation, it significantly eliminates and limits repetitive operations previously performed by the operator.

ITM Filter Technology

Next Generation Platforms for HNB and

Sustainable Products Manufacturing

Key Advantages

Automation

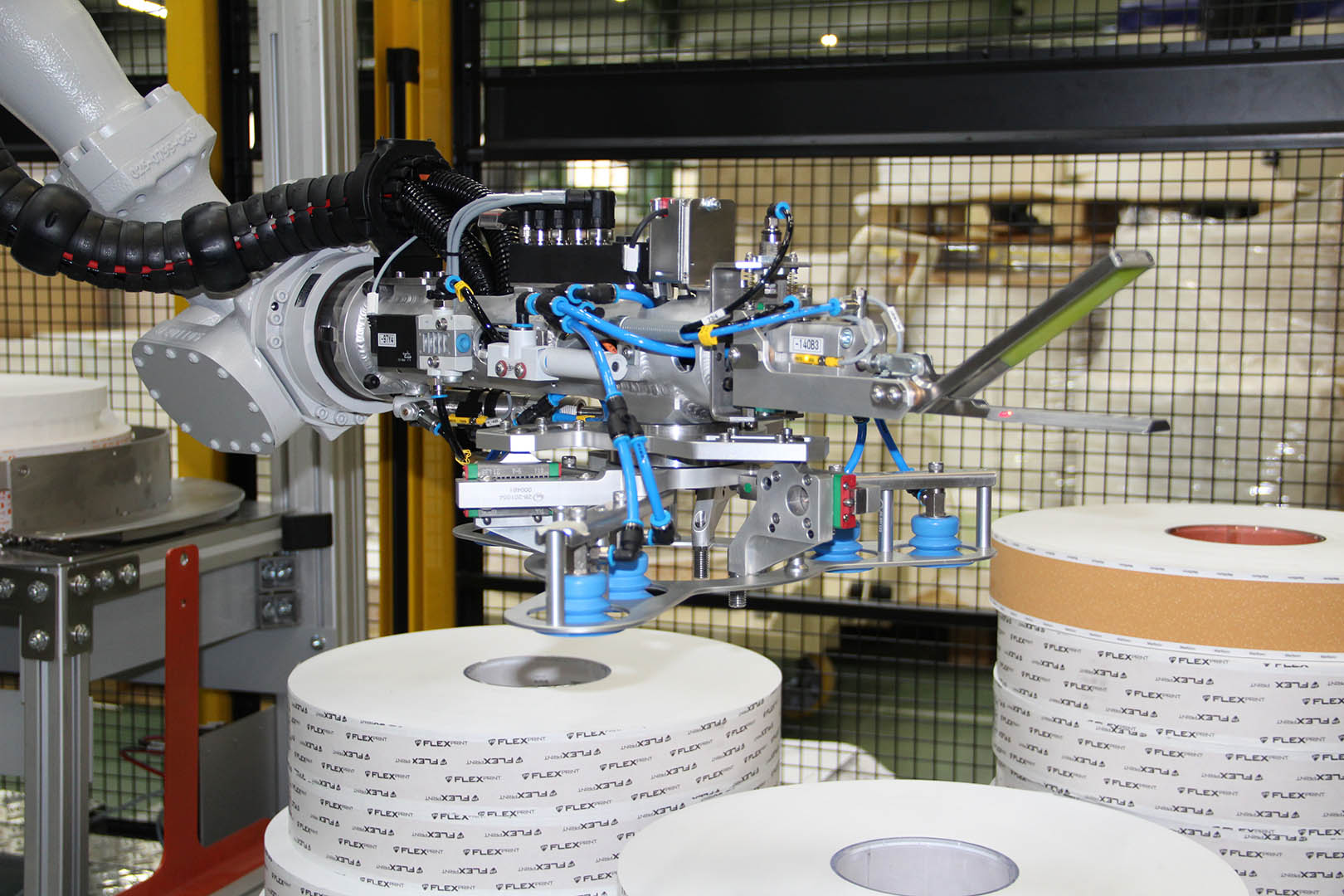

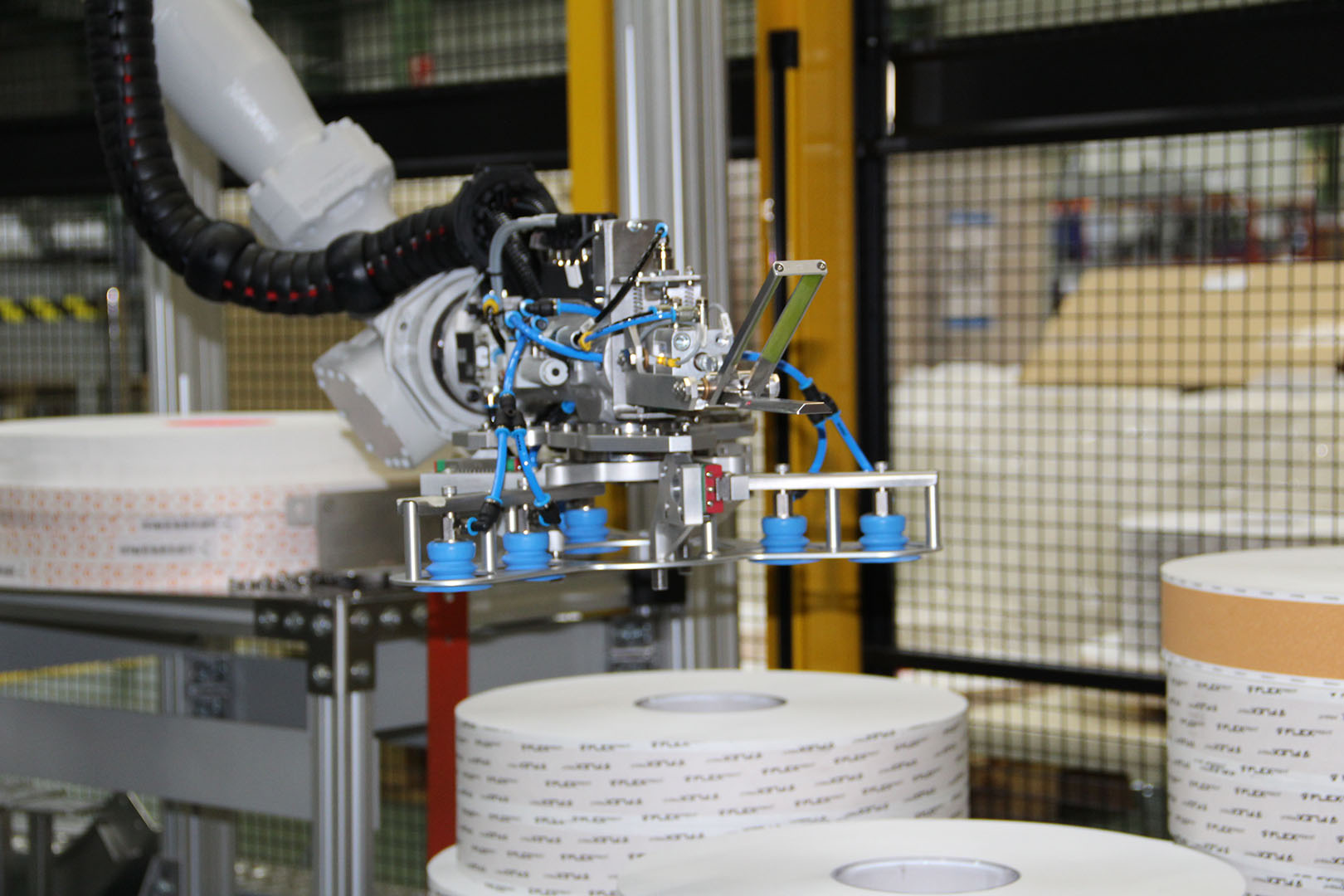

Versatility of the machine was one of the main design requirements of DBF. Technology of industrial robot allowed automation of many precise activities such as receiving the material, feeding it to different places and passing it between the rolls in a collision-free way. Apart from this DBF uses many vision systems owing to which we could locate different paper bobbins, regardless of their size, shape or position and read bar codes.

Team Product Process Development

Sustainability

At ITM we believe that it is not just about manufacturing. It is about constant development and providing more efficient, robust, and smart solutions for the industry. Our mission is to bring inspiration and implement innovation into every stage of production process. By reinventing and not just responding to the needs of today, we look forward to reshaping the world of tomorrow through SUSTAINABLE INITIATIVES.